Building Circularity Through Extended Producer Responsibility in Michigan

The Ocean Plastic Leadership Network technical expedition of Vancouver, British Columbia and Portland, Oregon recycling systems in May provided me with a closer look at extended producer responsibility (EPR) and deposit refund systems (DRS) in the Pacific Northwest. But more importantly, it started conversations and allowed me to ask questions to build my understanding of the variety of issues and opportunities around the development of these programs.

EPR: A Global Perspective

EPR exists in many countries around the world, including in the European Union, Canada, Latin and South America, Australia, China, Indonesia, Japan, and Mexico. Recycle British Columbia was the first full packaging and paper EPR program in North America. Ten years in, the BC program is beginning to chart new territory. They now collect a wide variety of packaging curbside including, plastic cutlery, straws, and dental floss and plastic tape dispensers at the curb and flexible plastics of all types at the drop-off. They regularly audit their recycling stream and are beginning to catalogue the variety of plastic and flexible packaging that comes through their system. Other Canadian provinces followed Recycle BC's lead, however, with only partial EPR programs that require local governments to pay for some portion of the program, although many of those provinces, including Ontario, will be moving to fully producer supported EPR programs in the coming year.

The Shift Toward Producer Responsibility

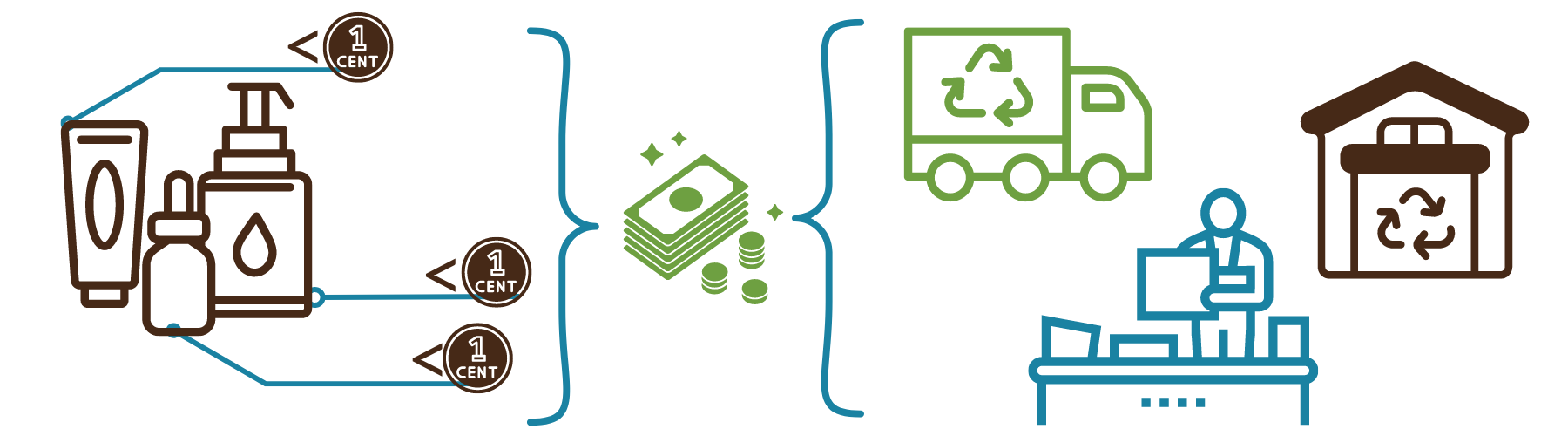

Under an EPR system, producers take financial responsibility for recycling consumer goods and packaging. Very simply, producers pay fees based on the products and packaging they produce and sell in Michigan, for example, and these fees are then used to cover the costs of recycling programs across the state.

EPR aims to internalize the end-of-life cost of the product and its packaging and reduce the financial burden on local government and taxpayers, thereby shifting some responsibility back onto the entity that has the most control over the product. From my perspective, EPR is an effective and equitable way to assure that the lifecycle costs of consumer products and packaging is at least partially covered. EPR is gaining steam in the U.S., too. Maine, Oregon, California, Colorado, and most recently Minnesota have passed EPR for consumer goods packaging and printed paper. Each program has a slightly different twist based on state need and capacity. But EPR is proving itself an effective way to fund and give access to services that put discarded materials back into production, essentially building the circular economy.

...but the investment needed to transform the way we manage end-of-life materials is much more significant than $15M

Michigan's Opportunity

Six short years ago the Michigan legislature approved $15M in annual funding for recycling for the first time ever. The Michigan Renew Fund amped up recycling investment and will financially provide for the updated county materials management planning process and implementation that all Michigan counties will begin next month. The resulting county plans will provide the local and collective vision and long term roadmap to grow recycling and composting to the benefit of Michigan communities. But the investment needed to transform the way we manage end-of-life materials is much more significant than $15M.

We’ve all heard the criticism about recycling. But we’ve just begun to invest in a system that aims to put waste back into productive use. The Michigan Recycling Coalition produced a report on the State of Recycling in Michigan in 2011 that pegged the needed statewide investment in recycling at $76M annually (over $108 million in 2024 dollars). The recent Colorado needs assessment that is required by their EPR statue, identified a medium scenario statewide recycling program cost at $190M-$310M annually – making it clear that without significant investment, the recycling system will continue to fall short.

Looking Ahead

You may be surprised that EPR policies are gaining momentum in the U.S. But there are already more than 135 EPR policies in place that cover a variety of materials from batteries to mercury switches to household hazardous waste. As we learn more about the degradation of plastic in the environment and impacts of micro-plastic on the health of living beings, it’s hard to deny that we need to do something differently now.

Internalizing the costs of the full lifecycle impacts of a consumer product and its packaging is an important step in responsible design and sale. In Michigan, it could mean that producers assure that all Michigan residents have recycling services at the curb or drop-off, effectively leveling up recycling opportunities for everyone and relieving taxpayers of recycling costs. EPR would reduce the burden of waste, encourage more sustainably designed products and packaging, provide recycled materials back to producers to make new products, and support to achievement of important sustainability goals for everyone across the supply chain.

Get Involved!

Excited about the prospects of EPR for Michigan? Check out our website, circularmichigan.org to learn about extended producer responsibility and what it means for you.

If we are to bring EPR to Michigan we’re going to need your help! Learn more about how you, your local government, or your organization can support here. If you think your community can pass a resolution in support of EPR, now is the time.

In the spring of 2019 the Michigan State University, Center for Community and Economic

Development undertook the exploration of EPR. The research team formed around this

project began their work by analyzing the EPR practices of Canada and Europe to identify

critical elements of successful models and the inherent challenges faced in their transitions. This

was followed by meetings with key Michigan subject matter experts who spoke with the

established faculty network. (see https://ced.msu.edu/events/contemporary-issues-institute/priority-actions-for-supporting-an-extended-producer-and-circular-economy-2020 )

In order to identify the short- and long-term pathways to a circular economy, the research team

gathered input and information from a broad set of stakeholders. The team utilized a modified

Delphi method survey to establish common topics which then advised the agenda for the

group’s virtual forum, held on May 20, 2020. Survey items were developed in five different areas relevant to the

circular economy including 1) Extended Producer Responsibility, 2) Recycling, 3) Public Policy,

4) Producer & Consumer Attitudes, and 5) Sourcing.

A collaborative forum served as the last phase of the Delphi technique. Each stakeholder who

received the two-round survey was also invited to attend the virtual forum. The program

consisted of a brief review of the research thus far, a guest panel15 of three subject matter experts

representing government, business, and a global non-profit to stimulate conversation, and then

small group discussions around the prioritized items identified through the survey. The groups

then reconvened to report on the conclusions found during these roundtable discussions.

It was found that a focused effort informed by research, financial implications, and accountability

are key factors in the success of extended producer responsibility initiatives. Incentives and

penalties, design and life-cycle analysis, and resilient supply chains will all be important elements

in the implementation of circular economy initiatives. Programs that center around product take-

back, reusable packing, and modular and repairable design have heightened interest among those

surveyed in this work and thus may serve as primary avenues for greater extended producer

responsibility and circular economy proposals.